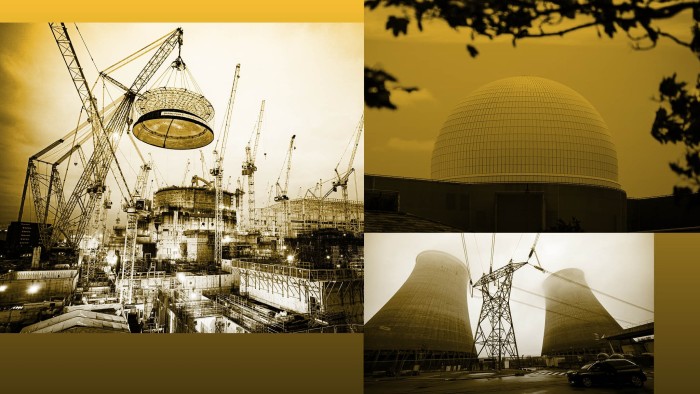

On a construction site sitting behind the beach at Sizewell, on England’s East Anglian coast, mountains of soil make it hard to see two small, blue signs. These indicate the spots where, in the middle of the next decade, two nuclear reactors should start generating enough energy to power 6mn homes.

The extraordinary thing about the 900-acre site is not its scale but that it has an identical twin — for reasons that reveal a lot about the latest thinking on building nuclear power stations.

The new Sizewell C plant has been designed to be as close as possible a copy of Hinkley Point C, a project 280 miles away on the other side of the country. Building there started in 2016, eight years before that at Sizewell.

The replication is part of a push across Europe and North America to tackle what Bent Flyvbjerg, an academic studying project management, calls the nuclear power industry’s “negative learning” problem.

More simply: for an industry that has become infamous for massive cost overruns and endless delays, maybe the solution is just to build exact copies of established reactors.

The industry is desperate to find ways to keep costs in check. In many countries, the more experience the nuclear power sector has gained, the more expensive and time-consuming it has become to build facilities.

“The more we’ve learnt about how to do nuclear power, the more expensive it’s got,” Flyvbjerg says. “That’s the opposite of what usually happens.”

For many politicians and economic planners, nuclear power has to be an essential part of the energy transition because of its ability to provide large, predictable amounts of power without producing carbon emissions.

Fatih Birol, executive director of the International Energy Agency, an intergovernmental group, has called for a “new era for nuclear energy”. According to the IEA, there are 63 reactors, with a total output capacity of 70 gigawatts, under construction worldwide, one of the highest levels in the last 30 years.

But that will require defeating the cost and timeline problems that have long plagued the industry. The IEA has also found that nuclear plants delivered since 2000 in the US and Europe were on average eight years late and cost two-and-a-half times their original budget. The UK government on Thursday announced planning reforms intended to make it easier to build nuclear plants quickly and cheaply.

Flyvbjerg, who holds posts at Oxford’s Saïd Business School and Copenhagen IT university, says that, compared with other megaprojects, nuclear power plants are “more expensive”, “much slower” and “much more complicated”.

Yet there are widespread hopes that standardisation — of the kind planned for Sizewell C — might be key to resolving the challenge.

“That’s the way to produce a positive learning curve,” Flyvbjerg says. “The only hope that we have is to replicate what we’ve done and see if the positive learning curves finally show up.”

A coalition of 31 countries has set an ambition of tripling the world’s nuclear energy capacity by 2050.

There is particularly intense interest in the sector as a potential source of power for the fast-growing data centre industry. The steam that drives electric turbines in a nuclear power station can also be used for a range of other purposes, including heating nearby housing, running chemical plants, generating hydrogen or even potentially making steel.

There are especially high hopes that a new breed of reactors produced on assembly lines in factories, known as small modular reactors, might make replication easier in the future.

Some countries, including Russia, China, South Korea and the United Arab Emirates, claim to have far better records on cost control and delivery. An IEA report published in January said that two recent projects in South Korea — Saeul 1 and 2 — were delivered only two and five years late and only 30 per cent over budget.

However, Birol accepts the current picture is mixed.

“We’ve seen that in Europe and the US the cost didn’t go much down because there’s no continuous process of building nuclear power plants,” he says.

Tom Burke, founder of E3G, a London-based clean energy consultancy, is far more sceptical, saying the information from the countries claiming better records lacks credibility.

“Where the publicly available information is reliable — if you look at what happened in Finland, the United States and the United Kingdom — people have not built reactors to time and budget, ever,” Burke says.

Luc Rémont, chief executive of EDF, the French, state-owned electricity company that owns a 23.9 per cent stake in Sizewell C and is providing the technology, has blamed governments’ stop-start approach to building nuclear power plants for creating difficulties.

EDF, which built 56 nuclear reactors between 1974 and 1989, was once admired as one of the world’s most reliable builders. But it has faced years of delays and cost overruns on its three most recent projects — at Olkiluoto in Finland, at Flamanville in France and at Hinkley Point C.

Hinkley Point C — the UK’s first nuclear power plant since the opening in 1995 of Sizewell C’s neighbour Sizewell B — was originally scheduled to open in 2025 at a cost of £18bn. It is now projected to start producing power in 2029 at the earliest and to cost £46bn in 2024 prices.

Rémont told attendees at this year’s World Economic Forum in Davos that the company had learnt lessons from recent experience “successfully, though painfully” and stressed the importance of minimising design changes between successive projects.

France’s state auditor, the Cour des Comptes, in January recommended that EDF should delay making a final investment decision on Sizewell C until it has reduced its exposure to Hinkley Point C. A final UK government decision on whether to go ahead with the full project, beyond the preparatory work already under way, was due last year but has been postponed until some time this year.

Rémont said that EDF could avoid the past mistakes by building future plants — including Sizewell C — on a “fleet” basis, using the same design for each.

“We didn’t have to build enough over the last 20 years to be able to scale it,” Rémont said. “Each time we had to build one, we had to reinvent it partially — and partially means totally. We need to accelerate the pace of construction by repeating the same thing and not reinventing the wheel.”

Many energy experts remain sceptical, however, that even a far more standardised nuclear industry would deliver cheap, clean energy. Governments have over decades introduced steadily more onerous rules for the sector as new potential risks emerged.

Flyvbjerg says there have been waves of tightening of safety rules after each of the industry’s rare but high-profile accidents — at Three Mile Island, in Pennsylvania, in 1979; at Chernobyl, in then Soviet Ukraine, in 1986; and at Fukushima, in Japan, in 2011.

Safety and environmental rules have become stricter in many sectors in the industrialised world in recent years — last year, for example, it emerged that the UK’s HS2 high-speed rail project had been forced to spend £100mn on an elaborate tunnel to protect a colony of bats.

But Flyvbjerg points out the phenomenon has been particularly marked in nuclear projects. One of the many challenges for Hinkley Point C has been how to ensure no fish are sucked into the intake for its cooling water systems from the neighbouring Bristol Channel.

“When we first started doing nuclear power, it had one cost,” Flyvbjerg says. “Then we did some more and the cost went up and we did more and the cost went up further.”

These increases are all the more perplexing because civil nuclear power is such a long-established technology. The world’s first civil nuclear power station — at Calder Hall, in Cumbria, England — opened in 1956.

Michael Bluck, director of the Centre for Nuclear Engineering at Imperial College, London, describes the technology behind most of the roughly 420 reactors operating worldwide — the light water pressurised water reactor (PWR) — as so routine as to be “not very interesting”. Nearly all the nuclear reactors under construction worldwide — including those at Hinkley Point C and Sizewell C — are PWRs.

“We understand PWRs better than we understand any other form of nuclear reactor,” Bluck says. “That means we understand their demands on components; we understand how to manufacture them.”

Projects can start to go wrong, according to Patrick Fragman, chief executive of Westinghouse Electric, the US-based designer and builder of nuclear reactors, when national regulators refuse to accept that a design cleared for building in another country can be safely built on their territory.

EDF has said UK regulations meant there were 7,000 changes to the design for Hinkley Point from that at Flamanville — although the UK’s Office for Nuclear Regulation has disputed the figure.

Fragman says that Westinghouse refuses to modify its reactor design, the AP1000. Westinghouse was forced into bankruptcy protection in 2017 because of cost overruns on the Vogtle plant in Georgia and another project in South Carolina. While the South Carolina project was abandoned, Vogtle’s two AP1000s are now fully operational and there are four AP1000s operating in China.

Westinghouse is negotiating deals to build plants using the AP1000 in Ukraine, Bulgaria and Poland.

“You get the US design — nothing more, nothing less. Basically, you can choose the colour,” Fragman says.

EDF’s Rémont said that it was vital for European safety regulators to take a common approach, to allow the sector to operate at an appropriate scale.

“If we don’t have that, it’s going to be a pain, which is what we’ve had over the last two decades,” he said.

Many in the nuclear industry point to the United Arab Emirates as an example of how to avoid other countries’ mistakes. The state-owned Emirates Nuclear Energy Corporation built four pressurised water reactors between 2012 and 2024 at Barakah, on the country’s Gulf coast. While there were some delays, particularly with the first reactors, Enec insists that the project’s cost — widely reported as $32bn — has been in line with original projections.

Mohamed Al Hammadi, its chief executive, rejects suggestions that the UAE has cut corners or built to a lower standard than other countries, pointing out that the Korean-designed reactors that the company installed have been licensed by the US’s nuclear regulator.

“I got all of the support from government institutions and also the private sector in the UAE,” he says. “People saw the determination and the will to do this to high standards.”

Many developers’ hopes are hanging on a new breed of reactors — small modular reactors. The devices are intended to be small enough to mass-produce on a highly standardised basis in the controlled environment of a factory. They will then be taken to power station sites for installation. Most SMRs will have a capacity below 300MW, less than 10 per cent of the 3.2GW capacity at Sizewell C, and will be far smaller.

ČEZ, the Czech Republic’s state-owned electricity generator, in October signed a deal to buy multiple SMRs, with a total capacity of up to 3GW, from an arm of UK aero engine maker Rolls-Royce. ČEZ also took a 20 per cent stake in the business, Rolls-Royce SMR. The UK’s planning reforms announced last week are particularly aimed at encouraging the building of SMRs.

Rolls-Royce SMR is one of scores of companies developing plans to manufacture and sell the small reactors, although the only examples operating at present are one in China and two on a specially designed floating power station in Russia. Alastair Evans, corporate affairs director for Rolls-Royce SMR, says the company is doing everything it can to ensure its products will be fast to put in place.

Evans says the division was asked when it was established in 2015: “What is the fastest way to get megawatts on the grid?”

“They took the decision to have no innovation, particularly in the pressurised water reactor, the nuclear bit of it,” he says.

Yet even the simplest nuclear plants present difficult construction challenges. Such complex systems afford little chance during building for engineers to test whether individual segments are working effectively. The whole thing either works when powered up or fails.

“Imagine a tailor who has little experience with suits making a bespoke suit for you and having to get it right on the first try,” Flyvbjerg writes in his book How Big Things Get Done. “It’s not going to end well. And that’s just a suit, not a multibillion-dollar, fantastically complex nuclear power plant.”

The challenges are clear looking at the vast piles of earth that dot the Sizewell site. The material has been excavated because the soil underneath many of the key installations is too weak to support the future buildings. It will be replaced with better-quality material being dug up from a neighbouring part of the site. That has not been an issue at Hinkley Point C, which rests on solid granite.

Paul Dorfman, chair of the Nuclear Consulting Group, a group of nuclear-sceptic academics and experts, says the problem shows how even nuclear projects that are meant to be copies end up being unique.

“Each reactor is a first-of-a-kind, actually,” Dorfman says.

Nevertheless, Tilly Spencer, technical director of Sizewell C, insists her project is gaining tangible advantages from following Hinkley Point C’s lead. EDF has said Sizewell should be about 20 per cent cheaper than Hinkley Point to build and that Hinkley Point’s second reactor is proving 30 per cent quicker to build than the first. (Hinkley Point C is projected to cost £46bn in 2024 prices, while the Financial Times has reported cost estimates for Sizewell C have risen to £40bn. Sizewell C has not confirmed the reported rise in the price from a previously projected £20bn.)

Sizewell will be able to order components from the same suppliers that built parts for Hinkley Point and stockpile them, ready to install as soon as the site can accept them, according to Spencer.

Sizewell plans to overcome the soil quality problems not only by bringing in better soil from nearby, Spencer says, but also by sitting the key, nuclear parts of the plant on a “significantly thicker” concrete raft than at Hinkley Point.

“Over 85 per cent of the design will be an exact copy,” she says. “We’re able to take Hinkley drawings, put ‘Sizewell’ on them and build them.”

Rémont was clear. He portrayed the nuclear sector as having solved the challenges of recent years and being ready to fulfil its promise.

“Nuclear is back in the middle of the game,” he said. “We see our industry again attractive — with talent, with innovation.”

Yet sceptics such as E3G’s Burke are far from convinced.

Asked if he thinks steady orders and standardisation can bring the sector’s costs under control, Burke replies: “I think that’s one of the biggest ‘ifs’ I’ve ever seen.”