Anyone who’s used melamine knows it dents and cuts easily, unlike hardwood plywood or MDF. The secret to getting clean, chip-free cuts in melamine is using the right tool for the job.

This guide will take you through methods to cut melamine using a jigsaw, circular saw, and table saw, ensuring you get that smooth, professional finish every time.

Working with melamine can yield professional-looking results, but avoiding chips along the cut line is a common challenge many face.

Melamine, with its durable and smooth surface, is a popular choice for cabinetry, furniture, and shelving. However, its tendency to chip makes cutting it a bit tricky.

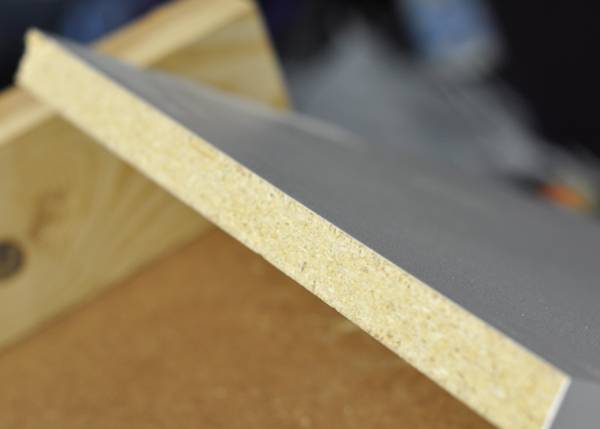

To achieve chip-free cuts, understanding the properties of melamine is essential. The core is typically made of MDF or particleboard, which can be prone to splintering when cut.

The key to a clean cut is using the right tools and techniques.

Making Melamine Cuts Without Chipping

The type of blade you choose is critical. Blades designed for laminates with a high tooth count are your best bet for reducing chips.

Each tool we discuss requires a specific blade to effectively handle melamine’s unique properties.

Preparation and setup are just as important as the cutting action itself.

Making sure your melamine is supported properly can make a significant difference.

This minimizes movement and vibration, which are often culprits behind chipping. Simple tricks like using masking tape along the cut line or making a scoring pass can also go a long way in protecting the surface.

Additionally, controlling your feed rate and maintaining steady pressure are crucial steps.

Rushing through the cut or forcing the tool can result in a rough edge and more chips. Instead, let the tool work at its pace, guiding it smoothly and consistently.

Cutting melamine cleanly improves the look of your finished product and makes assembly easier and more precise.

Each method we’ll cover has advantages and best practices, equipping you with the knowledge to tackle any project confidently.

Cutting Melamine with a Jigsaw

Use The Right Blade

Selecting the right blade when using a jigsaw to cut melamine is critical. Opt for a fine tooth blade designed for laminates. The high tooth count helps produce smoother cuts and minimize chips.

Melamine Facing Down

Make sure the good side of your melamine faces down while cutting, as this technique helps keep potential splintering on the non-visible side.

Use Masking Tape

Adding a layer of masking tape along the cut line can also help reduce chipping. The tape supports the melamine surface during cutting, leading to cleaner results.

Before starting your cut, take a moment to ensure the tape is firmly adhered to and that your cut line is marked.

Steady Pressure

Another key factor is maintaining steady, even pressure as you guide the jigsaw.

Let the tool do the work at its own pace to avoid forcing it through the material, which can cause rough edges and increase the likelihood of chips. Using a slower, controlled feed rate enhances the quality of your cut.

Secure Melamine

To further support the melamine and reduce vibration, make sure it’s properly secured.

Clamping your workpiece can help prevent unwanted movement during the cut, providing better stability and reducing the risk of kickback.

Techniques for Cutting Melamine with a Circular Saw

Using a circular saw to cut melamine effectively involves careful preparation and technique. Start by selecting a fine tooth blade with at least 80 teeth.

This blade type handles delicate surfaces like melamine, MDF, and particleboard, ensuring a clean cut with minimal chips.

Set The Blade Height

Next, set the blade height so it just clears the surface of the melamine. This adjustment reduces the tear-out on the back of the board, producing a smoother edge.

A blade with a high alternate top bevel (ATB) design or a scoring blade can make a big difference for optimal results. These blades slice through the melamine coating cleanly, crucial for achieving that chip-free finish.

Support Melamine

Supporting the melamine sheet properly is essential. Place the sheet on a stable surface and support both sides to prevent sagging.

Use clamps

Using clamps to secure the sheet can help keep it steady during the cut, reducing the chance of movement that can lead to chipping.

A useful technique is to make a scoring pass before your main cut. This involves setting the blade depth to just a fraction of the melamine’s thickness and creating a shallow cut along your cut line.

This initial pass gently breaks through the surface layer, significantly reducing the risk of chipping when making the full-depth cut.

Maintain steady feed rate

Maintaining a steady feed rate is also important.

Push the saw smoothly and consistently through the material, letting the blade do the work. Forcing the saw or moving too quickly can result in rough edges and increased chipping.

Keep hands safe

Keeping your hands safe while ensuring a smooth cut is vital. Use a guide rail or straight edge to align your circular saw with the cut line. This extra guidance can help maintain a straight cut and improve the overall quality of your edge.

By paying attention to these details and setting them up properly, you can achieve professional-quality cuts in melamine with a circular saw.

Strategies for Using a Table Saw to Cut Melamine

Using a table saw to cut melamine can be a game-changer for achieving precise, chip-free edges.

To get started, focus on the blade setup. A fine tooth blade with a high tooth count is essential for clean cuts.

Make sure the blade is sharp

Dull blades can cause chipping and produce rough edges.

A zero-clearance insert is one of the most effective strategies for cutting melamine with a table saw.

This insert fits snugly around the blade, providing maximum support and preventing the melamine from bending into the saw blade’s gullet. The result is a smoother, cleaner edge with minimal chipping.

Blade height also plays a crucial role

Set the blade so it barely clears the surface of the melamine.

This minimizes tear-out and ensures a smooth cut.

Some woodworkers prefer using a scoring blade for the initial pass, as it helps break the melamine’s surface layer gently, further reducing the risk of chips when making the full-depth cut.

Support the material

Supporting the material is just as important as the blade setup. Ensure the melamine sheet is well-supported on both sides to prevent sagging or shifting during the cut. Using feather boards or hold-downs can help keep the melamine in place and reduce vibration, which often causes chipping.

Steady feeding

Another key aspect is feeding the material through the saw at a steady, consistent rate. Avoid forcing the melamine through the blade too quickly, as this can lead to rough edges and increased chipping. Instead, let the saw do the work while you maintain control.

Use push blocks

Use push sticks or blocks to keep your hands safe and the material steady. These tools help guide the melamine through the saw while keeping your hands safe from the blade.

Check your setup

Finally, always take the time to check your setup before cutting.

Make sure everything is aligned, the blade is at the correct height, and the material is securely supported. This attention to detail will help you achieve professional-quality cuts in melamine with your table saw.

Frequently Asked Questions

Can I use masking tape with any of these tools to prevent chipping when cutting melamine?

Absolutely, using masking tape is a tried-and-true method to minimize chipping when working with melamine.

By applying tape along the cut line, you help stabilize the surface fibers, resulting in a cleaner cut.

How can I ensure my table saw fence is properly aligned for precise melamine cuts?

First, check that the fence is parallel to the saw blade by measuring the distance from the blade to the fence at both the front and back.

Adjust as necessary to eliminate any deviation, as even a slight misalignment can lead to uneven cuts and increased chipping.

Is there a difference in blade teeth count that is optimal for cutting melamine with different types of saws?

The tooth count on a blade significantly impacts the quality of the cut.

For table saws, a blade with a higher tooth count, typically around 80 to 100 teeth, is recommended for clean cuts on melamine, while circular saws can achieve good results with blades in the 60 to 80 tooth range.

How does the feed rate affect the quality of cuts when using a table saw on melamine?

Maintaining a steady, moderate feed rate with a table saw is crucial for achieving smooth cuts on melamine.

Pushing the material too quickly can cause the blade to tear the surface, leading to chipping, while going too slowly might result in burn marks.

Conclusion: Mastering the Ideal Cut

Each tool—jigsaw, circular saw, and table saw—offers unique advantages for cutting melamine, making them suitable for different tasks and project requirements.

The jigsaw shines when you need to make curved or intricate cuts. Its versatility and ease of handling make it a go-to tool for detailed work. With the right blade and technique, you can achieve smooth, chip-free cuts.

The circular saw is a powerful option for straight cuts, offering both portability and precision. It’s particularly useful for larger sheets of melamine, where maneuvering a table saw might be challenging.

By using a fine tooth blade and setting the blade height correctly, you can minimize chipping and achieve clean edges.

The table saw, however, stands out for its precision and stability. It’s the best choice when you need consistently straight cuts with immaculate edges.

A fine tooth blade and a zero-clearance insert can significantly reduce chipping, giving you a professional finish every time.

Which Tool To Choose?

No matter which tool you choose, preparation is key.

Ensuring your melamine is well-supported and stable can prevent movement and vibration, two major causes of chipping.

Simple techniques like using masking tape along the cut line or making a scoring pass can also enhance your results.

Your feed rate and pressure during the cut are equally important.

Whether using a jigsaw, circular saw, or table saw, maintain a steady pace and let the tool do the work. Rushing or forcing the cut increases the risk of chips and rough edges.

Practice is essential.

Take the time to test your setup on scrap pieces of melamine. This allows you to fine-tune your technique and make necessary adjustments without the pressure of working on your main project.

By paying attention to these details and consistently applying the right techniques, you can master chip-free cuts in melamine.

Your confidence and skill will grow with each project, allowing you to achieve professional-quality results.